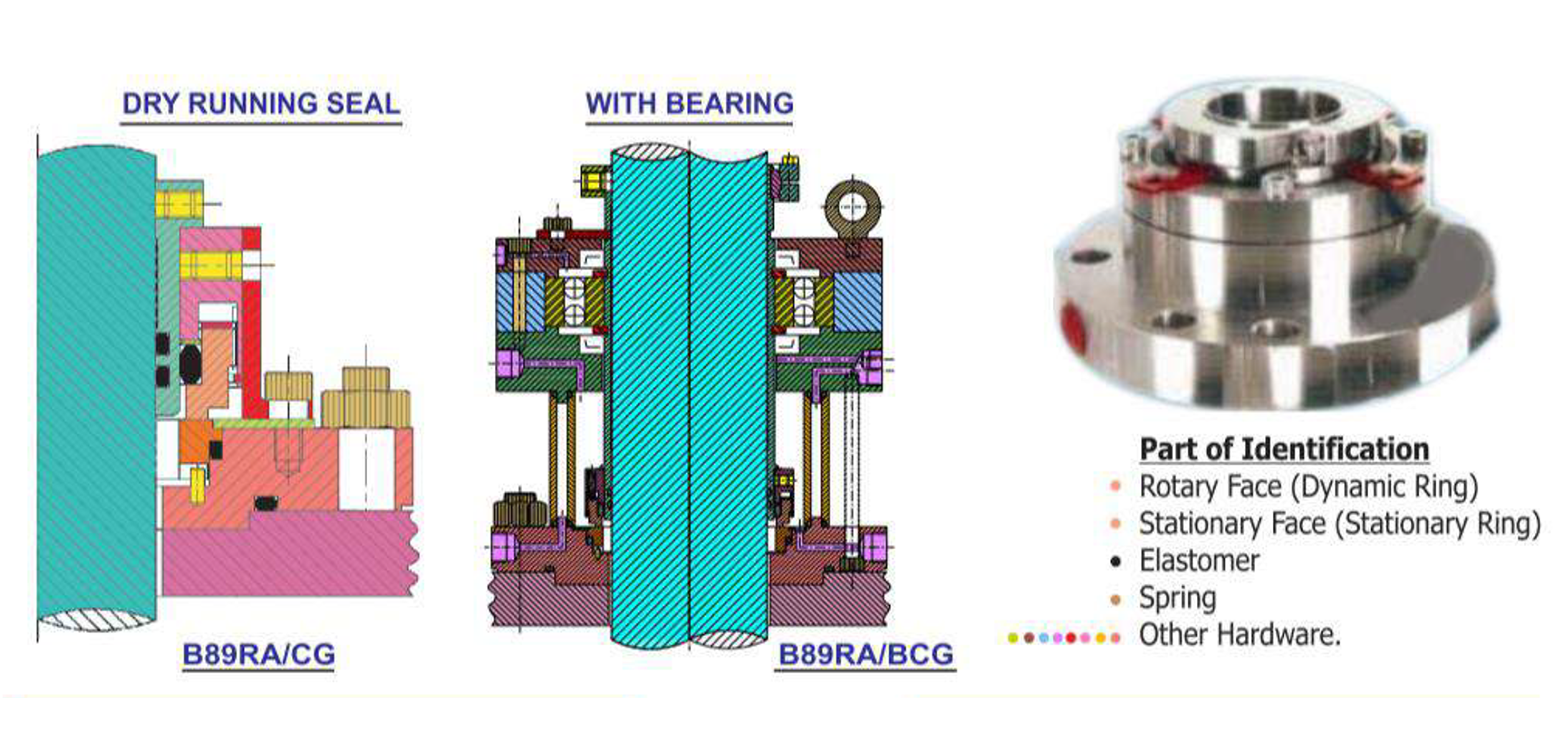

GLOBE STAR Agitator Make B89RA/CG Seals of Series is Factory Assembled & Dynamically Tested units on Steel glass lined and SS Mixers, Agitator & Vessels. These Seals are basically used on Top Entry Agitators as Dry Running Seals. When Food Products or Pharmaceutical Products are Agitated in Agitator Mixing of any Other liquid will contaminate the Product & Affect its Quality Hence these Dry Running Seals are used These Seals don't require any External media for Lubricating. The Faces that is why They are Known as Dry Running Seals dentification of the Seal Size is done by the Outside Diameter of the Sleeve.

This is a Multiple Spring Externally Mounted, Balanced Seal with "O-Ring" as Secondary Sealing Member. Various Face Materials & Elastomers can be offered for wide service Application. This Seal can also be used for Corrosive Services as the Metallic Components. i.e. Retainer, Spring, Washer etc, do not come in contact with liquid to be Sealed. These type Seals are available in two types with Bearing or without Bearing.

Globe Star Standard Style

| Face Material | (Dynamic Ring & Stationary Ring) Carbon, Ceramic (99.5%) Silicon Carbide, Tungsten Carbide, Chrome Cast Steel....etc. |

| Elastomer | (Secondary Seal) Viton, EPDM, Aflas, PTFE, GFT, TCV & FEP, Kalrez. |

| Hardware | SS-316, SS-304, Hast alloy-C, Monel, Alloy-20 |

Application :

- General Light Chemicals

- Food Products

- Pharmaceutical Products

- Corrosive Chemicals

Operating Limits :

- Shaft Diameter :- 20mm to 150mm (0.75" to 5.875")

- Pressure :- 20 Bar (Kg/cm²)

- Temperature :- 125°C (Maxi)

- Shaft Speed :- Upto 6000 RPM According to Shaft Size & Pressure.

Seal Characteristics :

- Outside Mounted

- Independent of Direction of Rotation

- Reverse Balanced

- Dry Running Type

- Single Acting

Other Available Dry Running Seal